The MEOR technology

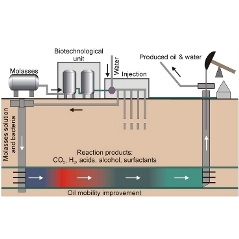

For MEOR treatment of oil reservoirs previously selected bacteria are bred in fermenters on site and injected into the underground formation together with a molasses media. MEOR can be applied as a cyclic ("huff and puff") or as a continuous flooding process. Together with injection water selected microorganisms are injected deep into the reservoir, where they multiply and ferment the introduced nutrients (molasses).

Deep inside the reservoir trillions of microorganisms generate a number of production increasing substances, which lead to reduction of water cut and a significantly increased crude oil production rate.

Bacterial products and their impact on oil production

Bacterial gases

| Microbial Products | effects | Oil field parameters |

| CO2 (80 %), H2 (20 %) up to 380 ml per gram of molasses, | Increase of pressure up to 20 bar in model experience | Increase of energy potential in the oil field |

| CH4 as final product from organic acids, alcohol's and hydrogen | Increase of oil volume factor and therefore decrease of oil viscosity | Increase of oil mobilization |

| Change of pressure potential in fissures and pores | Increase of oil production rate |

Organic acids

Microbial Products |

effects |

Oil field parameters |

Acetic-, propionic-, nutyric-, valerianic acid |

Decrease of pH down to 4.8 |

Increase rock permeability |

Dissolving of carbonatic rock by ~0.2 ton per ton molasses |

Extension of oil production to fresh not yet drained rock |

|

Build up of new flow channels |

Alcohol's, biolipids

Microbial Products |

effects |

Oil field parameters |

Methanol, ethanol, propanol, butanol |

Decrease of inter-factional tension (for example against heptane down to 12 - 46,5 mNm-1) |

Force imbibition of injected, fermented molasses media into pore canals and fissures to give more oil from the rock |

Biolipids |

Alteration of rock wettability |

Break up of oil/water barriers and creating emulsions, |

Effects of the MEOR-technology have been proven in numerous studies and applications:

- Increase of energy potential inside the reservoir

- Improvement of pressure potential in fissures and pores

- Decrease of oil viscosity

- Reduction of oil/water surface tension

- Improvement of capillary adsorption of liquids

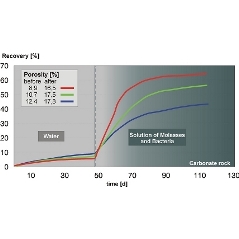

- Increase of permeability by rock dissolution

In numerous tests and field application the oil production could be enhanced by more than 100 %.

Minimizing the risks

For a successful application of the MEOR technology we strongly recommend field-specific preliminary investigations. This involves the evaluation of reservoir parameters and analysis of formation waters. More detailed preparations are carried only in case the reservoir is in principle suited for MEOR treatment.

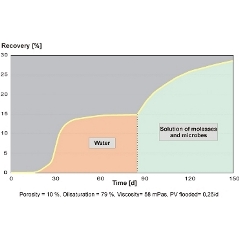

A simulation of the MEOR process in model experiments on basis of original samples enables a reliable prognosis of anticipated oil extraction rate and enhanced oil production. This reduces the economic risk level significantly before a field application.

A pilot test on a representative section of the reservoir with injection and production wells can provide us with concrete information about profitability of the MEOR process within a short period of time.