MEOR case study - oil field “Doebern” (Germany)

The oil field “Doebern” (Zechstein carbonate, fissured-porous) is located in a depth of ~1,200 m. The combination of temperature, 53°C and saturated formation water (NaCl) were specific requirements for bacteria used for the MEOR treatment. In the first MEOR phase the biotechnological unit was operated discontinuously. During the last years of operation continuous flow rates of 0.4 m3/day and a cell content of 4*108 bacteria/ml was established at a salinity of 150 g/l.

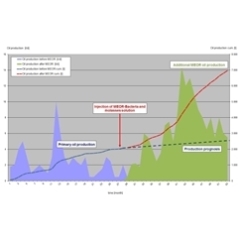

For example, we injected 2,000 m3 of nutrient solution with 50 ton of molasses with polyphosphate and soda as additives, in a mixture of fresh and formation water. Following this an adapted cell mixture in a ratio of 1 to 10 was injected. After injection the well was closed in, and effectiveness of the molasses-in-situ technology was observed at a production well located 600 m from the injection well by monitoring the production well shut-in pressure.

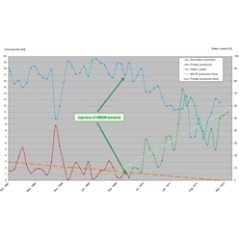

Before the MEOR treatment the producing well flowed with 88% water. After injection water content decreased substantially to a minimum of 34%, and to an average of 60%. The water decrease in the output clearly shows increased oil desorption from reservoir by activity of microorganisms.

Production results

Before the beginning of MEOR treatment the average annual oil production was 50 tons/month (1.6 t/day). Three months after injection of nutrient molasses solution and bacteria we observed an increase of oil production to an average of 150 tons/month. Despite the considerable distance between injection well and production well the CO2 content in gas phase increased from 0 - 0.2% to 4% near the end of the project. About a year after injection we observed a further increase of oil production to an annual average of 300 tons/month. For a period of four months the daily oil production of 12 - 14 tons reached an eight-fold of the initial output.

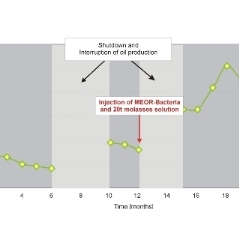

In addition to this long-time flooding treatment we also tested the huff-and-puff method in carbonate reservoir rocks. After injection of bacteria and 20 tons of molasses the oil production rate increased (without changing the procedure) from 7 m3/day to 14-17 m3/day, and the oil output from 0.5 to 2.5 tons/day. Additionally, the wellhead pressure increased by 2 MPa through a biogas generation. This production enhancement is attributed to improvement of flow conditions in the formation by a microbial rock solution processes.