MEOR case study - oil field “Romashkino”

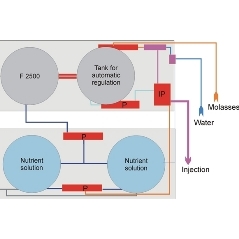

For the field application at the oil field “Romashkino” (Tatarstan) an automatically controlled fermentation plant was designed for a mass cultivation of the bacteria genus Clostridiae. This biotechnological unit consisted of two containers, mounted on sledges. One container included technical equipment for medium production, as nutrient salt tank, media tanks, pumps etc. The second container contained vaporizers for sterilization, fermenters for inoculation and cultivation, mixing line for preparation of injection medium and injection pump. The plant was automatically controlled by bacterial activity of Clostridiae-culture in the main fermenter.

For the pilot test at Romashkino oil field this type of plant was used which guaranteed a planned injection volume of 3.000 m3 per well.

Production results

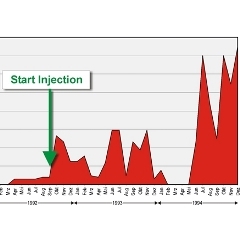

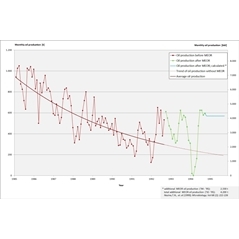

Production tests show that the gas/oil ratio considerably increased by methane gas generated during the molasses fermentation process in the reservoir. For the entire oil field ratio increased from an average value of 3.6 - 4 to 7.8 in 1993 and 8.5 m3 gas/m3 oil in 1994. Wells which were specifically influenced by MEOR revealed ratios between 16 and 20 m3 gas /m3 oil1.

Improved flow conditions in the reservoir and increased gas/oil ratios led to an enhanced net oil production by 50% to 65% without changing production regime. The water content of the entire field was reduced from 74% to 57%. Between 1992 and 1995 the MEOR treatment resulted in an additional MEOR oil production of 4,200 ton (26,400 bbl)

Additional positive effects of MEOR were recorded:

- Reduction of oil density: from 0.950 to 0.907 g/cm³

- Reduction of oil viscosity: from 83.3 down to 24,0 mPa s

- Reduction of surface tension by up to 25 %

1 Nazina, T.N. et. al (1999) Microbiologiya 68(2);252-260; 261-266